- Home

- PRODUCTS

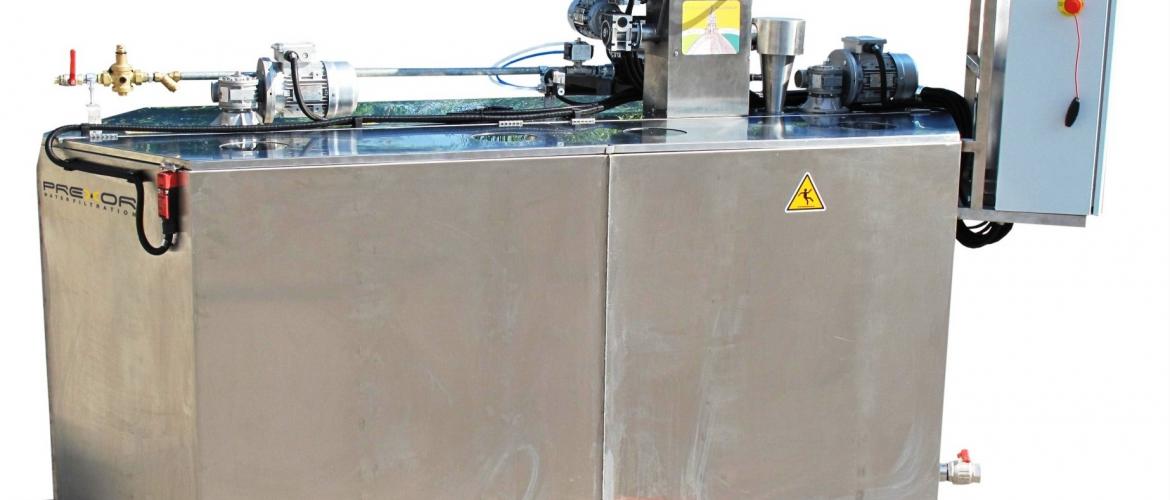

- STAINLESS STEEL FLOCCULANT UNIT

STAINLESS STEEL FLOCCULANT UNIT

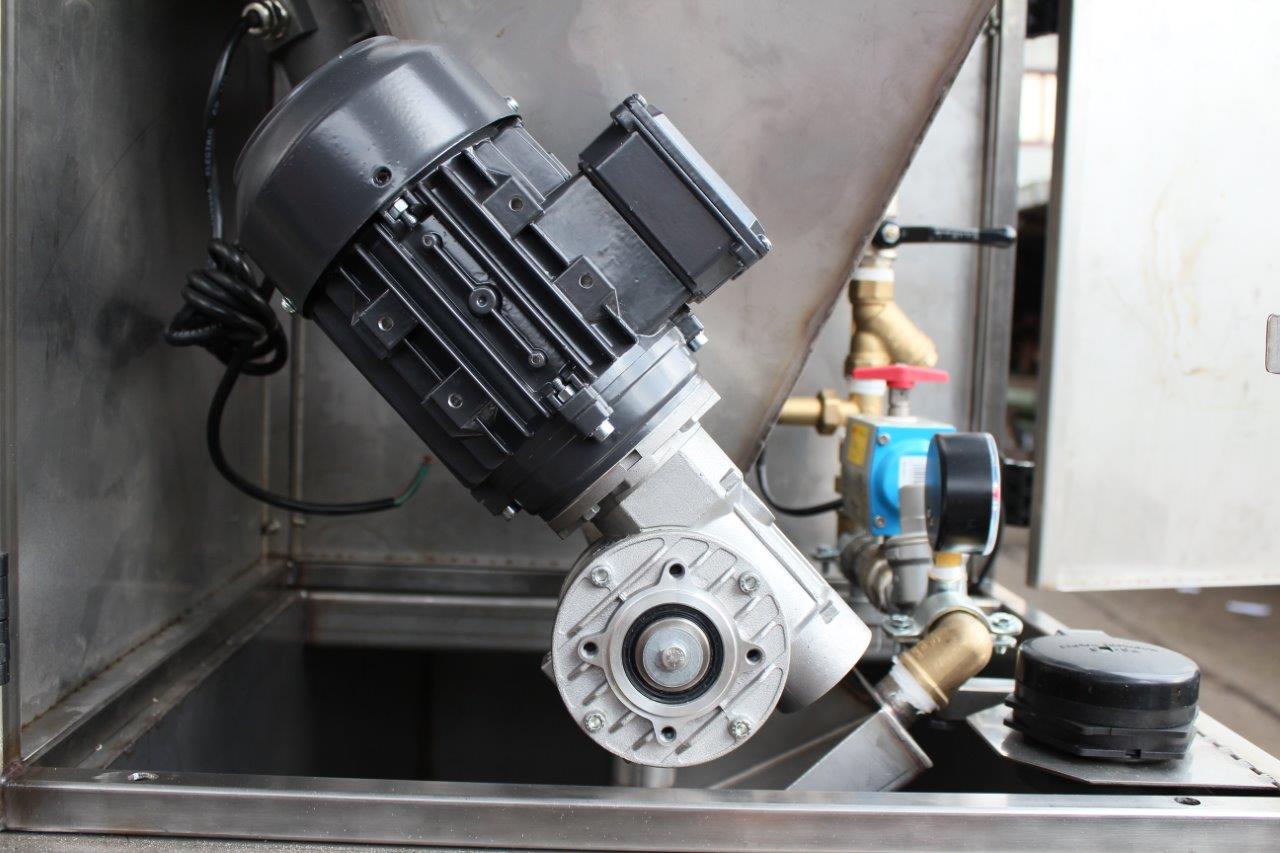

The polyblender stations are designed to fully manage the characteristics of the flocculant, ensuring its dilution at an optimal concentration. In particular it consists of stainless steel tanks for dissolution, agitation and dosage of the polyelectrolyte. Particular attention is paid to the dosage of flocculant powder with the use of 3 anti-bridge systems.

Technical features "Plus" version:

- Polygonal structure with bridge for gearboxes and auger in metallic carpentry, centrally positioned

- Increased maturation tank, for greater operating autonomy

- Full coverage of the compartments with hinged and removable covers with support stand

- Automatic pause switches when opening the hopper and the hoods

- Adjustable 4-position ISO probe holder assembly

- Stainless steel stirrers with blades of different speeds

- Powder disperser with lid funnel cone, all in stainless steel

- Exclusion valves for water line maintenance, upstream of the dismountable and inspectable filter

- Hopper with stainless steel lid

- Anti-condensation system with Joule effect

- Double-action system with double mechanical action

- Nylon screw with square tooth obtained from solid; the winding pitch is such as to allow a correct and stable powder conveyance

- Plexiglass polyelectrolyte powder level inspection window

- Polyelectrolyte deficiency alarm probe

- Panel on silent blocks with Schneider-Telemecanique components

- C.s Schneider

- Impulse flow meter for concentration management. L.C.D. panel management / display of the main machine parameters

- 400 V three-phase 50 Hz power supply

- IP 55 protection rating